Early this summer when we first turned on our AC, I noticed that it wasn’t generating very cold air in comparison with previous summers. When I checked the unit downstairs, every bit of exposed copper piping had frozen over, and when I went to check the outside unit, the condenser was also frozen. I knew this wasn’t good, so I shut off the AC, and began trouble shooting in the most DIY way possible; that is, I went through the simplest fixes that I “knew” how to do, and then Googled others when those solutions didn’t work.

These are the steps I took to ultimately fix my AC. I’m also including my failed steps to show my logic, and the various things that may be wrong with yours

- With the unit off, I allowed the pipes to defrost, and ran around the house opening all the vents throughout the floors. Our house is big and has an addition, so in order to cool the upstairs sufficiently we shut almost all the vents on the first floor. This forces the cooler air generated by the AC to the second floor, and then this “heavier” cooler air settles to the first floor naturally. This hack has allowed us to effectively cool our larger, oddly arranged house layout.

My hypothesis was, since it was the first time we turned the unit on this summer, and we “spiked” it to combat the heat, perhaps I overtaxed the system bypassing the “easier” 1st floor vents. Result: The unit turned back on, the second floor got uncomfortably warm, AND the unit froze up again! - Next I went outside to check the status of the screen around my unit. At our previous house, the AC unit was in a wind tunnel that carried a ton of particulate matter that clung in the filter screens. An HVAC guy told me that by rinsing these regularly, I could extend the life of my unit and in extreme cases keep it from freezing up. So I turned the AC off again, went outside, and sprayed down the screens. There was a bit of debris in the screens, but nothing like at our last house. I wasn’t very confident, this was going to fix anything, but I need to get in teh habit of cleaning these filter screens anyway Result: Turned the unit back on, and it froze again.

- Even though I recently changed the filters, I figured it was worth checking them again since we just had a bathroom remodeled and maybe the dust caused by the demolition prematurely clogged them. Result: Nope…still froze up.

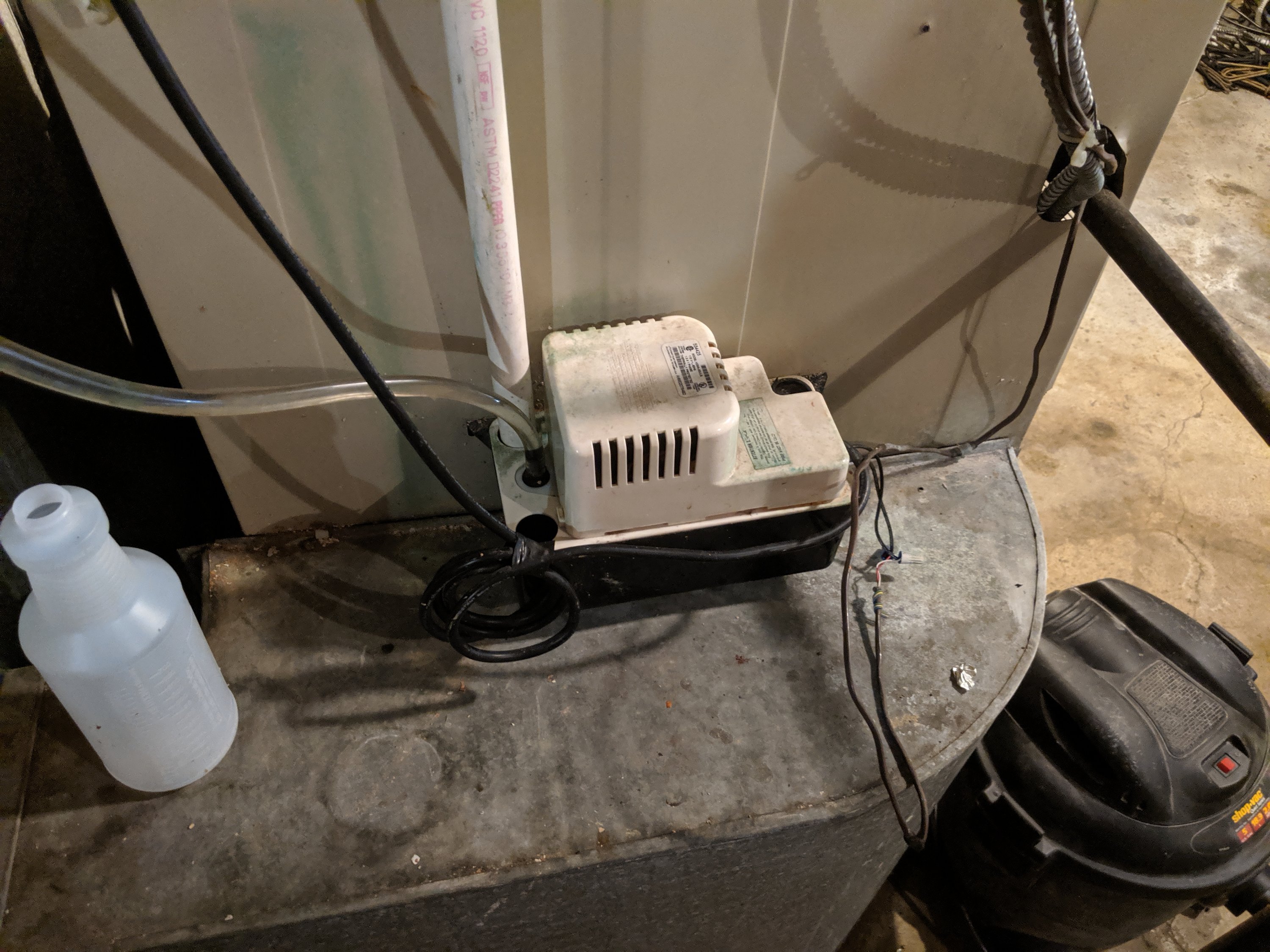

- Here I got frustrated and afraid. I was nearly certain I was going to need to break down and concede defeat, because I was running out of ideas. Result: I Googled other DIY fixes to un-thaw an perpetually freezing AC unit…this is where I learned about the condensation pump! (At our previous house, I’m pretty sure we didn’t have a pump because the unit was on the first floor and raised on a platform that allowed the unit to drain via gravity. I was always curious what the thing pictured below was on our AC unit — turns out, that’s the pump!)

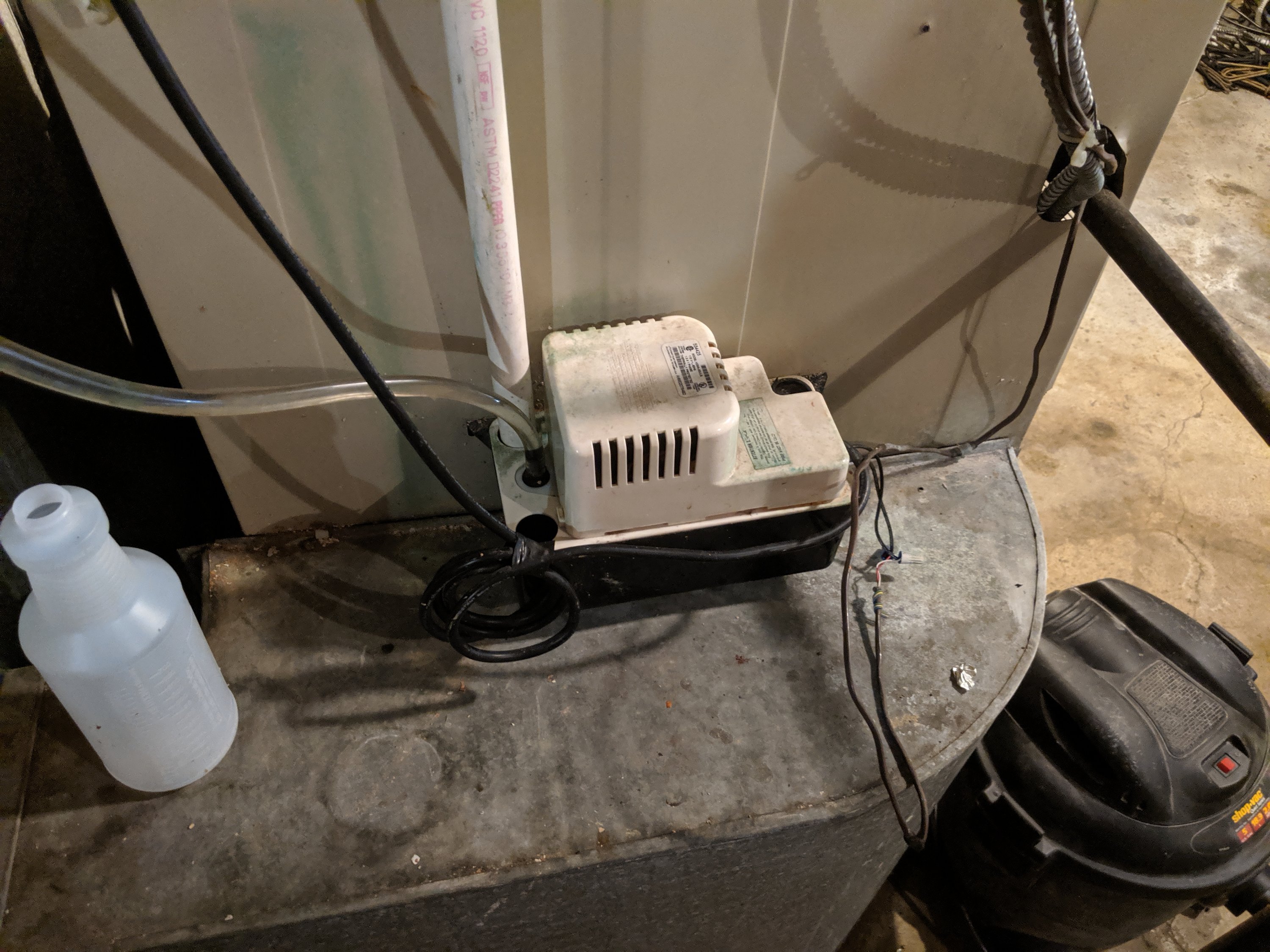

- Ran to the basement, and checked the pump (pictured above) to see if it was running properly. I unscrewed the white plastic top of the unit and to my surprise a cooling fan was whirring around at full blast, implying that the pump was currently running in the condensation reservoir. However, when I ran outside to check the condensation tube out there, no water was running out. So from here, I went back to the condensation pump and popped open the rubber top to the condensation tank. The water was to the brim of the unit, but it felt oddly slimy. Then I looked at the tubing coming out of pump, and realized that the “copper” piping coming from the unit wasn’t copper at all, but clear plastic tubing that was completely full of copper colored algae! I popped the tubing off to check to see what it looked like inside, and unfortunately forgot that the pump was still operational, and running…water shot out of the pump and jetted towards the ceiling. I unplugged the pump, and dried off my now wet arms. Result: I was wet, and I found at least one of my problems!

- I brought down a bottle of bleach and poured as much as I could in the reservoir. Since it was nearly full of condensation I couldn’t get much in, so I took a small amount of hosing I had laying around and attached it to the pump and put the other end into an empty bucket. I plugged the pump back in, and let the pump push all of the condensation water into the empty bucket. Now with a nearly empty condensation tank, I unplugged the pump and filled it entirely with bleach. After letting it sit for 30 minutes or so, I attached the hose back to the original condensation hose and turned the pump back on. The pump turned on, but could only force the bleach a few inches into the tube. I bent the tubing with the bleach running through it back and forth to break up and kill the algae. Because there was no air venting out of the system, the bleach would pump up only to the newly cleared tubing, and fragments of dead algae would settle back down into the reservoir with gravity. Because of this, I occasionally attached the surplus hose (I used earlier) to flush out the dead algae into my bucket and start the process over again with fresh bleach. I followed this process repeatedly, at about a foot at a time, for 3-4 hours until I got the tubing clear of algae all the way to where it exited the basement through the wall. There is a picture below of the freshly cleaned tubing with just a tiny fraction of algae left clinging to the wall of the tube. The picture following is of the tubing just before it leaves the basement, where you can see a larger build up of remaining algae.

Result: The condensation tubing was free and clear. - Although, I cleared the condensation tubing, I now noticed a tremendous amount of condensation running out and around the PVC piping from the AC unit to the pump reservoir I had just cleaned out.

Now I apparently had a completely “fresh” problem.This is where I nearly broke down and had an HVAC person come over.

However, after one last round of Googling, I found out that the condensation PVC will sometimes get bumped out of alignment and not allow the water to flow freely out of the unit with gravity. It then gets stopped up to the point where water will spill out wherever it can, and oftentimes runs along the outside of the PVC piping. Since I had been working around this area for so long, I thought that I may have bumped it out of place. So I took the PVC joints and piping apart, and found an unfortunate, or fortunate depending on how you look at it, surprise! The pipes fit together snugly, and they had an adequate slope out of the unit, however, when I ran my finger on the inside of the pipe, I pulled out nearly a tablespoon of black gunk! So either a different species of algae had grown up and into this PVC pipe, or the AC unit had been flushing sediment in its condensation that had built up over time. Since I didn’t have a pipe cleaner long enough to go through all the pipes and I didn’t want to risk pushing sediment back into the AC, I grabbed my wet/dry vac and pressed it as tightly as I could against the pipe that extended out of the unit. I heard a few satisfying seconds of sediment clacking around on the inside of my shop vac hose, and left it there until the only sound was the motor of the vacuum. I turned off the vacuum, reinstalled the PVC, and made sure that it had a natural slope into the condensation pump reservoir.

Result:

My AC unit turned back on, did not freeze up, and the condensation evacuation system worked as intended. I went back up and closed the vents on the first floor, and the second floor returned to its typical coolness level, and the AC still ran perfectly. So I fixed it! (***For now***). For only the cost of a bottle of bleach, and a few angry, but ultimately satisfying hours, I worked my way to a solution!